Packaging is the Science, art and technology of enclosing or protecting products for distribution, storage, sale and use. Functions of packaging includes containment, protection, preservation, communication, utility and performance.

Intelligent packaging can be defined as “packaging that contains an external or internal indicator to provide information about aspects of history of package and/or the quality of the food” (Robertson, 2006).Intelligent packaging is a type of packaging in which the elements of Intelligence like sensor, recorder, tracer and communicator are added either inside or outside of the food package.

Intelligent packaging is capable of carrying out intelligent functions like:

- Detecting

- Sensing

- Recording

- Tracing

- Communicating and applying scientific logic

- Extending shelf life

- Enhance safety

- Improve quality

- Provide information

- Warn about possible problems, etc

Intelligent packaging can be classified as :

- Sensors usually contain receptor and transducer. Receptor is the one which converts physical and chemical information obtained from food into the form of energy, where was transducers will measures the energy.

- Indicators will indicate the presence and absence of substance or the degree of reaction between two or more substances by means of a characteristic change, especially in color.

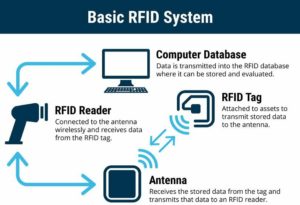

- RFID (radio frequency identification tags) is the use of radio waves to read and capture information stored on a tag attached to an object.

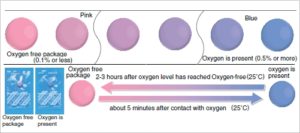

Gas indicators and sensors

Gas indicators will monitor the changes that are occurring in the gas composition inside the modified and controlled atmosphere food packaging. Metabolism and reaction of food products results in absorbing and releasing of certain type of gases which can be detected by the color change technology. It can also be used to indicate gas leak from active food packaging system.

products results in absorbing and releasing of certain type of gases which can be detected by the color change technology. It can also be used to indicate gas leak from active food packaging system.

Most commonly used gas indicator is Oxygen indicator, however carbon dioxide indicator is also available. Color of the oxygen indicator will be pink, if the amount of oxygen present in package is 0.1% or less, if it increases to 0.5% or more the color changes to blue. In oxygen indicator color change maybe the result of redox reaction or oxygen binding reaction.

Gas chromatography and gas chromatography mass spectroscopy (GCMS) are the destructive gas monitoring techniques which requires the package to be tampered before monitoring, this destructive gas monitoring techniques can be replaced by non destructive on-Pack sensor for monitoring the gas composition.

Time temperature indicator

Temperature influences the determination process directly that is at high temperature determination of food is relative lehigh does food safety and quality can be ensured by maintaining the correct storage temperature time temperature indicators. TTI works based on enzymatic reaction, polymerization and diffusion.

determination process directly that is at high temperature determination of food is relative lehigh does food safety and quality can be ensured by maintaining the correct storage temperature time temperature indicators. TTI works based on enzymatic reaction, polymerization and diffusion.

Based on the time temperature indicators response it can be classified as partial or full history indicator. Partial history time temperature indicator the sperms only when temperature exceeds over the threshold level there is the full history indicators gives the response to out the product history.

Radio frequency identification

Radio frequency identification tags are  advanced form of data information carrier that can identify and trace a product, provide security and promotion of quality and safety. RFID’s are affixed to container, pallet, package etc to obtain the real time information and transmit it to the user’s information system. Radio frequency identification uses radio waves to track the items wirelessly. The information provided by RFID can be stored and read by appliances. Few drawbacks of radio frequency identification tags are loss of signal due to absorption by water, high price and limited recycling ability.

advanced form of data information carrier that can identify and trace a product, provide security and promotion of quality and safety. RFID’s are affixed to container, pallet, package etc to obtain the real time information and transmit it to the user’s information system. Radio frequency identification uses radio waves to track the items wirelessly. The information provided by RFID can be stored and read by appliances. Few drawbacks of radio frequency identification tags are loss of signal due to absorption by water, high price and limited recycling ability.

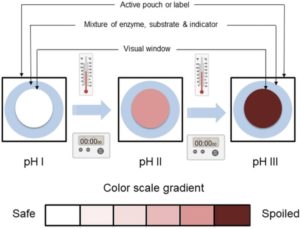

Freshness/Spoilage indicator

Freshness/spoilage indicator detect the growth  of microorganisms by reacting to the metabolites produced during growth of microorganisms such as carbon dioxide, ethanol, diacetyl, hydrogen sulfide and gives direct information about product quality. Color indicating tags are attached as small adhesive label to outside of packaging film to monitor freshness of perishable food products such as fruits, vegetables and seafoods. Metabolism also produces a few acids like lactic acid and acetic acid which can be detected by a pH indicator, thus color based pH indicator can be used as freshness/spoilage indicator. Different color indicates different stage of ripening.

of microorganisms by reacting to the metabolites produced during growth of microorganisms such as carbon dioxide, ethanol, diacetyl, hydrogen sulfide and gives direct information about product quality. Color indicating tags are attached as small adhesive label to outside of packaging film to monitor freshness of perishable food products such as fruits, vegetables and seafoods. Metabolism also produces a few acids like lactic acid and acetic acid which can be detected by a pH indicator, thus color based pH indicator can be used as freshness/spoilage indicator. Different color indicates different stage of ripening.

Biosensors/Nanosensors

These are the sensors which senses, records and transmit the information obtained from biological reactions. It consists of bioreceptors which are specific to target analyte and a transducer to convert biological signals to quantifiable electric response. Bioreceptors are the organic material such as enzymes, microbes, antigens, hormones, nucleic acids. Transducers maybe optical, electrochemical or calorimetric, and are system dependent.

Biosensors are made to detect the pathogen present in the food like Escherichia coli, Salmonella typhimurium, listeria monocytogenes, shigella flexneri, Salmonella species, staphylococcus etc. Few biosensors are called nanosensors which contain nanoparticles which get attached to pathogens or other contaminants and detects its presence through fluorescence or magnetic devices. The detection is mostly based on conductance or bioluminescence.

Future trends

Intelligent packaging is an emerging area in food technology which provide enhanced food preservation interest in this area and the number of food related applications is expected to increase significantly in the near future. Although Intelligent packaging may provide many benefits to shelf-life extension and food.

safety, there are several issues to consider before implementing such packaging systems. Compliance with food-safety regulations, high production costs and consumer mistrust have been found to be potential challenges. it seems very likely that future development will combine the benefits of active packaging with intelligent packaging system and will eventually end up in development of truly interactive packaging that responds directly to the needs of the food. Intelligent packaging can play an important role in reducing the role of pathogen contamination and extending the shelf life of food as well as improving convenience and traceability.