Circuit boards are delicate. Their performance can be impaired by the presence of the slightest moisture or dust. Most of the electronic breakdowns occur due to improper storage and packing of boards. Corrosion and short circuiting can be a result of humidity. Dust may cause connections to get blocked and decrease the life span of parts. These boards are secured by simple preventive measures to minimize expensive replacement.

In this guide, you will learn practical methods that keep your boards safe in storage, shipping, and daily use.

Why Moisture and Dust Are Dangerous

One of the largest threats to electronics is moisture. Industry reports indicate that moisture exposure during storage or shipping is a leading cause of failure of electronic products, about 20%. When water vapour invades a board, it results in corrosion and provides a pathway to undesirable current. This may cause a short circuit. Dust is another hidden risk. It accumulates on the board surface and retains humidity. With time, it inhibits performance and may lead to overheating.

You must keep boards in a stable environment and use the right protective layers. Once damage begins, it is often hard to repair. Prevention is always cheaper and faster than fixing.

Use a Proper Moisture Barrier for Electronics

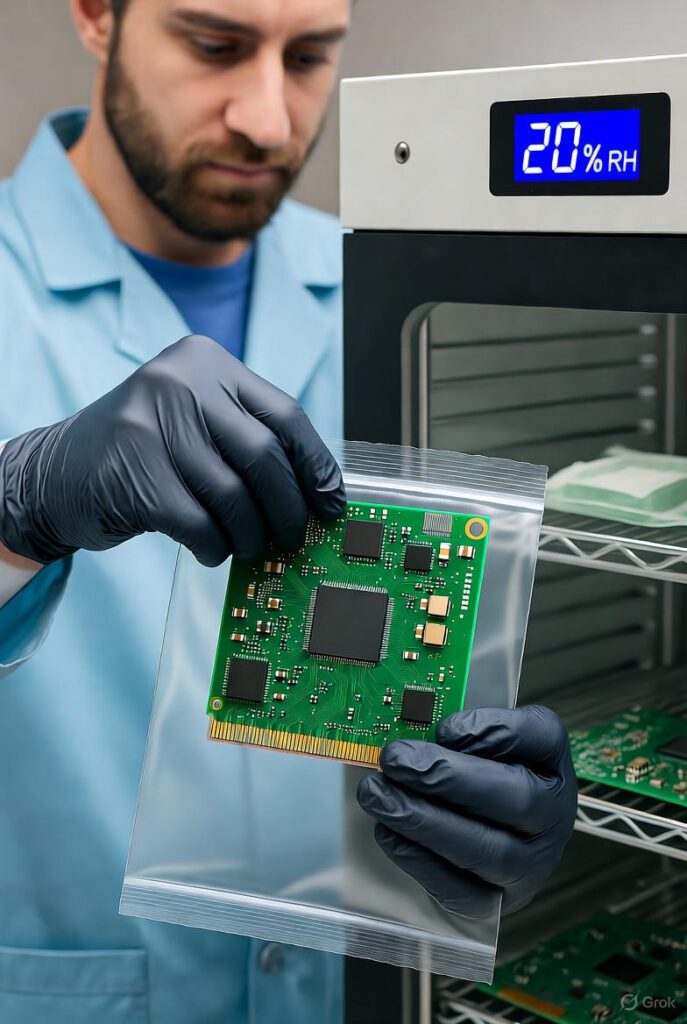

An electronics moisture barrier can prevent the entry of humidity when storing and transporting. This coating keeps the water vapour out of the board and destroys it. Aluminium foil laminate bags or multilayer films designed for use in electronics can be used. These are moisture-resistant and puncture-resistant materials. It is always important to close the package so that it can be airtight. Even such a slight gap will permit humidity to get in and destroy the protection.

Keep Boards in Clean, Dry Storage

Conditions of storage are important for protection. Select a clean and dry place of controlled temperature. Stay away from areas near open windows, air vents, or machinery that cause dust. Install simple humidity protection of electronic components to maintain a low level of moisture. Cabinets can be used with dehumidifiers or silica gel packs. Such practices ensure that the environment remains stable and is safe to store PCBs over short periods of time.

Put shelves with non-conductive trays on stack boards. Do not store them on wooden or metallic surfaces. Clean storage spaces frequently so as to eliminate dust. These PCB storage tips will help prevent the damage that often takes time to become noticeable until it breaks.

Use Moisture-Proof Packaging for Circuit Boards

Moisture-proof packaging for circuit board shipping or storage is essential. This packaging includes special barrier bags that block moisture and static. It is strong and lightweight. You can seal these bags with a heat sealer to make them fully closed. For extra safety, add silica gel desiccants inside each bag. These packets absorb any remaining moisture and extend protection time.

Custom mylar bags wholesale are a cost-effective option for large shipments. Mylar provides excellent moisture resistance and durability. It is also easy to label and store.

Apply Static Safe Packaging

Static discharge can destroy sensitive circuits instantly. This damage happens even before visible signs appear. Static safe packaging prevents this by using materials that discharge electricity slowly and safely. Use pink anti-static bags or metallic shielding bags, depending on the component sensitivity. Place boards inside these bags before adding outer moisture barriers. This two-layer protection guards against both static and humidity risks.

Grounding work areas and wearing wrist straps while packing also reduces the chance of static discharge. Simple habits like this prevent expensive failures.

Protect PCB from Humidity During Transit

Transport is risky because temperature and humidity change quickly. You should always prepare packaging for sudden shifts. Use moisture barrier bags, desiccants, and proper sealing. Cushion fragile boards with foam or bubble wrap to avoid vibration damage. Make sure boxes are labelled “fragile electronics” to alert handlers. Good labelling reduces mishandling during shipping.

For bulk orders, pallets should be shrink-wrapped to block environmental exposure. Choose transport services that understand how to ship fragile electronics safely. A small investment in proper handling reduces transit losses significantly.

Maintain Clean Handling Areas

The finest packaging does not work when there is dust or moisture in the handling areas. Keep workstations clean. Whenever possible, use air filters or simple cleanroom techniques. Gloves should be put on the workers so that they do not transfer moisture or oil to the boards. Airborne dust is contained by regular cleaning of fans, vents, and filters.

Do not unpack boards in open areas where the air is moist or dusty. Design a restricted unpacking area. These measures minimize contamination, which usually occurs at the final production step before assembling.

Practical Protection Checklist

Here is a simple list you can follow to keep boards safe:

- Use a moisture barrier for electronics during storage and shipping.

- Control humidity in storage rooms with dehumidifiers or silica gel.

- Keep storage areas clean and dry to block dust buildup.

- Pack boards in moisture-proof and static-safe packaging.

- Add desiccants to bags for extra moisture control.

- Cushion boards properly during shipping to prevent physical damage.

- Label packages clearly for careful handling.

- Maintain clean handling zones to avoid contamination.

This checklist is easy to apply and gives immediate improvements in protection levels.

Regular Inspection and Rotation

Protection does not consist solely of packaging. Stored circuit boards should be inspected by you frequently. Check to see whether there is moisture, dust, or corrosion. Turn stock to ensure that old boards are used first. This minimizes the possibility of degradation in the long term. Change silica gel packs once loaded. Record inspection history to also monitor trends and identify problems in time.

Long-Term Strategies

Invest in the use of controlled cabinets or dry boxes in long-term storage. These units are low-humidity and minimise manual input. Conformal coating of boards can be done as well. This is a skin-deep protective coating that is resistant to moisture and dust, but will not interfere with performance. It can be utilized in boards that are not used for months or that cover a long distance.

In high-value products, use several layers of protection. Store in moist barrier bags on the outside, use stat safe packaging inside, and maintain good environmental controls in storage.

Concluding

When you take the correct steps, it is very easy to ensure that you protect circuit boards against humidity and dust. Control the environment. Use proper packaging. Handle boards carefully. Frequent inspections prevent the accumulation of damage over time. A little care today means expensive repair bills tomorrow. Use these techniques in your storage and shipping procedures to ensure your boards can last several years.

Leave a Reply