In CNC machining, precision is not achieved by machines alone. It depends on how accurately the workpiece is positioned, supported, and repeated across production cycles. This is where jigs and fixtures play a decisive role in maintaining consistency and reducing variation. When parts are held correctly, machining operations become more predictable, efficient, and reliable, even under high-volume production demands.

As industries push for tighter tolerances and faster turnaround times, manufacturers can no longer rely on generic workholding solutions. Purpose-built tooling that aligns with part geometry and machining strategy has become essential. In CNC environments, properly engineered devices improve stability, reduce setup time, and directly influence product quality, making them a core element of modern precision manufacturing.

Importance of Jigs and Fixtures in CNC Operations

Supporting Dimensional Accuracy

Accuracy in CNC machining starts before the cutting tool touches the material. Jigs and fixtures locating systems ensure that each component is positioned relative to a fixed datum. This controlled positioning eliminates guesswork and ensures that dimensions remain consistent from the first part to the last. When every workpiece is aligned the same way, variations caused by manual adjustment are removed.

This level of accuracy is critical in industries where components must fit together without additional modification. By holding parts rigidly and consistently, workholding devices allow machines to perform at their full capability. The result is improved dimensional control and a noticeable reduction in machining errors.

Enhancing Production Repeatability

Repeatability is the foundation of scalable CNC production. Once a fixture is set up correctly, operators can load and unload parts with minimal effort while maintaining identical positioning. This repeatable process is especially valuable in batch and mass production environments where efficiency and consistency must coexist.

Reliable repeatability also supports quality assurance. Inspection results become more predictable, and corrective actions are easier to implement when deviations occur. Over time, this stability improves process confidence and reduces the cost associated with scrap and rework.

Core Elements of Jig and Fixture Design

Locating Principles and Datums

Effective jig and fixture design begins with clear locating principles. The objective is to restrict unnecessary movement while allowing easy loading and unloading. Designers commonly apply established locating methods that constrain all degrees of freedom using minimal contact points. This approach ensures accurate alignment without over-constraining the part.

Key locating considerations include:

- Establishing reliable datums based on part geometry

- Using hardened pins or surfaces to resist wear

- Maintaining accessibility for machining tools

When these principles are applied correctly, the fixture becomes a stable reference throughout the machining cycle, supporting both accuracy and efficiency.

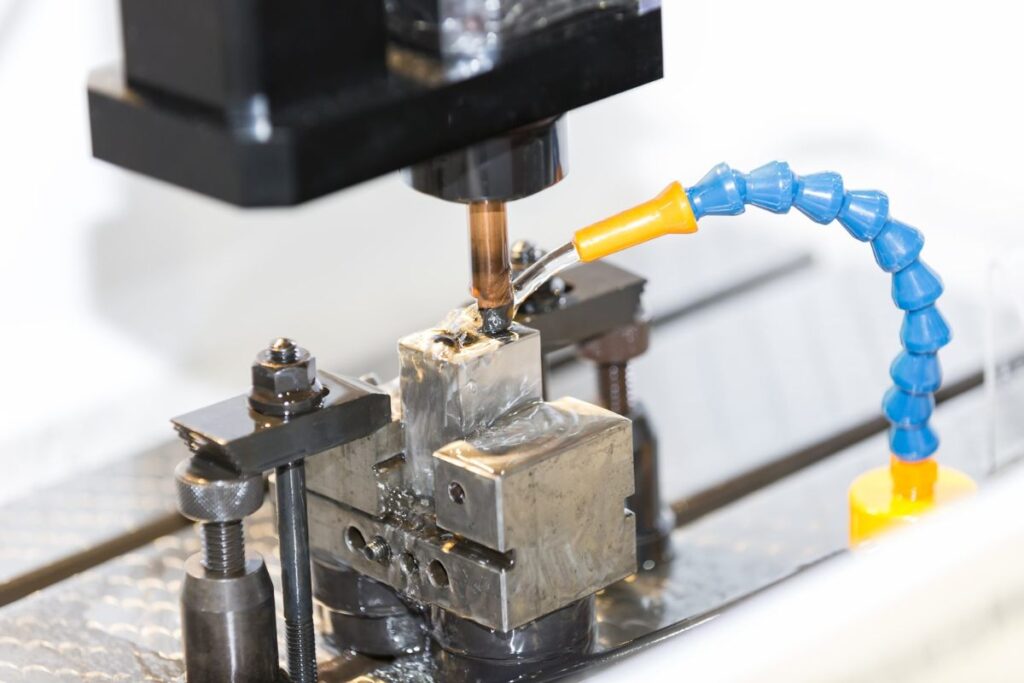

Clamping Strategies and Stability

Clamping holds the part securely against locating elements during cutting operations. The challenge lies in applying sufficient force without deforming the workpiece. Thoughtful clamping strategies consider material properties, cutting forces, and tool paths to maintain stability under load.

A well-balanced clamping system reduces vibration and prevents movement during machining. This stability directly impacts surface finish and tool life. By optimizing clamping force and placement, designers ensure that the fixture supports precision without introducing stress-related distortion.

Role of Jigs and Fixtures Tooling in Productivity

Reducing Setup and Changeover Time

Time spent setting up machines does not add value, yet it significantly affects production efficiency. Custom jigs and fixtures tooling simplifies setup by providing predefined locating and clamping points. Operators can prepare machines quickly, reducing downtime between jobs.

Faster changeovers are particularly valuable in high-mix production environments. When fixtures are designed for ease of use, shops can respond quickly to new orders without compromising accuracy. This flexibility strengthens overall manufacturing responsiveness.

Improving Operator Efficiency

User-friendly fixtures reduce dependency on highly specialized skills. Clear locating features and intuitive clamping mechanisms allow operators to perform setups confidently and consistently. This reduces the likelihood of errors and shortens training time for new personnel.

As operator efficiency improves, machines spend more time cutting and less time waiting. Over extended production runs, these gains translate into measurable cost savings and improved throughput.

Integration With Advanced CNC Technologies

Compatibility With Multi-Axis Machining

Modern CNC machines often feature four- and five-axis capabilities that allow complex geometries to be machined in fewer setups. Fixtures must support this flexibility by providing secure holding while leaving tool paths unobstructed. Advanced jig and fixture design accounts for machine kinematics and tool access from multiple directions.

By enabling multi-axis machining, well-designed fixtures reduce the need for repositioning. Fewer setups mean fewer alignment errors and better surface continuity, resulting in higher-quality finished parts.

Supporting Automation and Robotics

Automation is becoming standard in CNC manufacturing, and workholding solutions must adapt accordingly. Automated systems rely on fixtures that provide consistent positioning for robotic loading and unloading. Any variation can disrupt the entire process.

Automation-ready fixtures often include standardized interfaces and self-locating features. These characteristics ensure reliable operation across shifts and production cells. As automation expands, robust fixture design becomes a key enabler of lights-out manufacturing.

Application-Specific Jig and Fixture Design

High-Precision Manufacturing Requirements

Certain industries demand extremely tight tolerances and flawless consistency. In these cases, jig and fixture design must consider factors such as thermal expansion, vibration, and long machining cycles. Precision fixtures use rigid materials and finely machined locating surfaces to maintain stability under demanding conditions.

Attention to detail in these applications ensures that fixtures do not become a source of error. Instead, they enhance machine accuracy and support the production of critical components with confidence.

Handling Complex Part Geometries

Irregular shapes and thin-walled components present unique workholding challenges. Standard fixtures may fail to provide adequate support, leading to deformation or chatter. Custom devices are designed to match the part’s contours, distributing forces evenly and maintaining rigidity.

These tailored solutions allow manufacturers to machine complex components efficiently. By adapting the fixture to the part, shops expand their capabilities and reduce the risks associated with challenging geometries.

Benefits of Custom Jig and Fixture Design Devices

Long-Term Cost Efficiency

While custom jig and fixture design devices require an initial investment, they often deliver substantial long-term savings. Reduced scrap, fewer rejected parts, and shorter cycle times contribute to a lower cost per unit. Over the life of a production program, these savings can significantly outweigh the initial expense.

Custom devices also extend tool life by minimizing vibration and uneven loading. This further reduces operational costs and improves overall equipment effectiveness.

Consistent Quality Across Production Runs

Consistency is a hallmark of professional manufacturing. Custom-designed fixtures ensure that each part is produced under the same conditions, regardless of operator or shift. This uniformity simplifies inspection and strengthens customer confidence in product quality.

By maintaining consistent positioning and support, fixtures become a silent contributor to brand reliability and manufacturing excellence.

Future Direction of Jigs and Fixtures in CNC

Digital Design and Simulation

Advances in digital design tools are transforming how fixtures are developed. CAD and simulation software allow designers to test concepts virtually, identifying potential issues before production. This approach shortens development cycles and improves first-time success rates.

Simulation also enables optimization of locating and clamping strategies. Designers can refine fixture performance without costly physical trials, resulting in more efficient and reliable solutions.

Modular and Flexible Systems

Manufacturing demands are constantly changing, and flexibility is becoming increasingly valuable. Modular jig and fixture systems allow components to be reconfigured for different parts while maintaining precision. This adaptability supports low-volume, high-mix production without sacrificing efficiency. Flexible systems help manufacturers respond quickly to new projects. By combining modular elements with sound design principles, shops achieve both versatility and accuracy.

By integrating carefully engineered jigs and fixtures into CNC processes, manufacturers gain control over accuracy, repeatability, and productivity. Thoughtful design, proper locating, and stable clamping transform workholding into a strategic advantage, supporting high-quality output and long-term manufacturing success.

Leave a Reply