Radio Frequency Identification (RFID) is the wireless non-contact use of radio frequency waves to transfer data. Tagging items with RFID tags allows users to automatically and uniquely identify and track inventory and assets. RFID takes auto-ID technology to the next level by allowing tags to be read without line of sight and, depending on the type of RFID, having a read range between a few centimeters to over 20+ meters.

This technology is way more secure than coding because the companies use electromagnetic fields attached to the products which would be identified automatically. This process is the most secure method for AIDC or Automatic Identification and Data Capture.

RFID can be attached to everything including clothing and different possessions or even with cash. It can also be attached with living beings like pet animals and even people. However, modern day retail market has been blessed with the invention and upgrade of this technology. Let’s check out some of the names of the world’s leading companies providing RFID.

Radio Frequency Identification (RFID) - Types and Applications

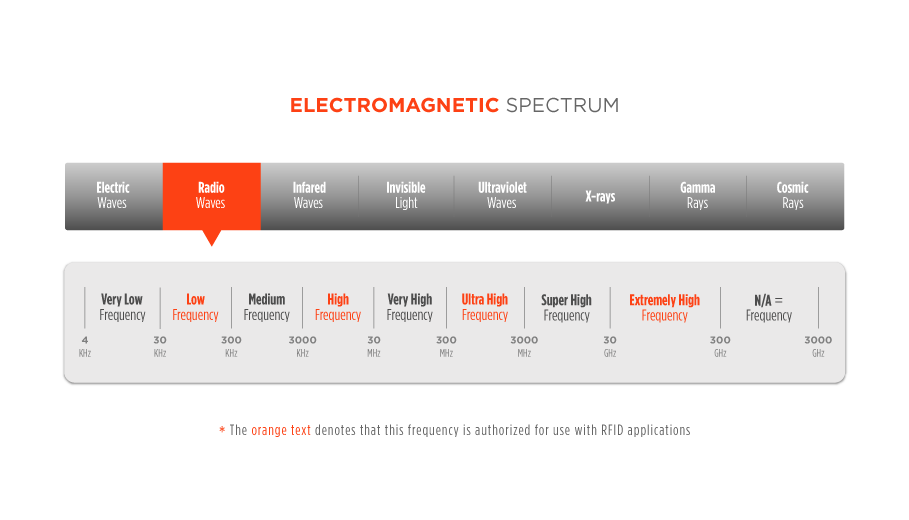

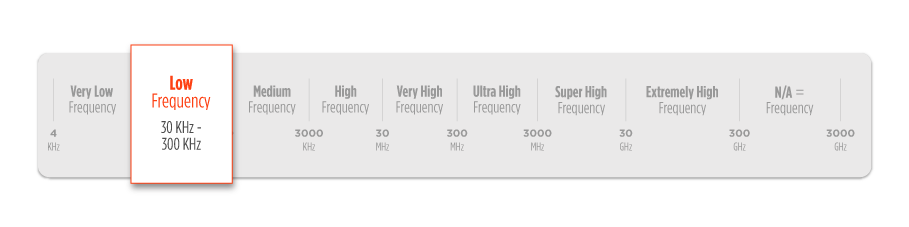

Within the Electromagnetic Spectrum, there are three primary frequency ranges used for RFID transmissions – Low Frequency, High Frequency, and Ultra-High Frequency.

Low Frequency General Frequency Range: 30 - 300 kHz

General Frequency Range: 30 - 300 kHz- Primary Frequency Range: 125 - 134 kHz

- Read Range: Contact - 10 Centimeters

- Average Cost Per Tag: $0.75 - $5.00

- Applications: Animal Tracking, Access Control, Car Key-Fob, Applications with High Volumes of Liquids and Metals

- Pros: Works well near Liquids & Metals, Global Standards

- Cons: Very Short Read Range, Limited Quantity of Memory, Low Data Transmission Rate, High Production Cost

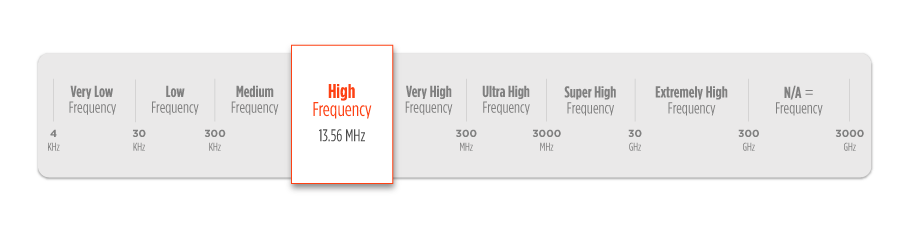

Primary Frequency Range: 13.56 MHz

Primary Frequency Range: 13.56 MHz- Read Range: Near Contact - 30 Centimeters

- Average Cost Per Tag: $0.20 - $10.00

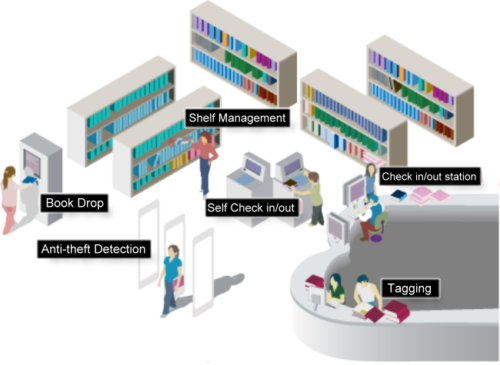

- Applications: DVD Kiosks, Library Books, Personal ID Cards, Poker/Gaming Chips, NFC Applications

- Pros: NFC Global Protocols, Larger Memory Options, Global Standards

- Cons: Short Read Range, Low Data Transmission Rate

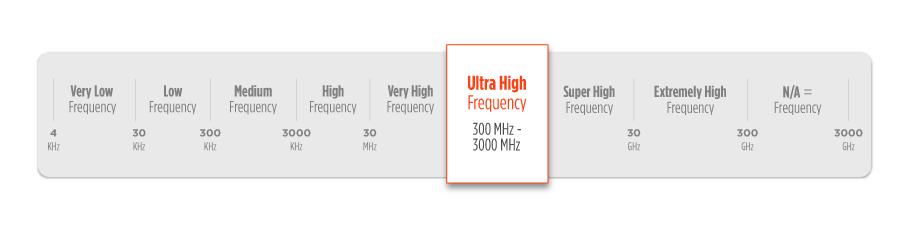

Ultra-High Frequency

Ultra-High Frequency

- General Frequency Range: 300 - 3000 MHz

- Primary Frequency Ranges: 433 MHz, 860 - 960 MHz

- Primary Frequency Range: 433 MHz, (Can use 2.45 GHz - under the Extremely High Frequency Range)

- Read Range: 30 - 100+ Meters

- Average Cost Per Tag: $25.00 - $50.00

- Applications: Vehicle Tracking, Auto Manufacturing, Mining, Construction, Asset Tracking

- Pros: Very Long Read Range, Lower Infrastructure Cost (vs. Passive RFID), Large Memory Capacity, High Data Transmission Rates

- Cons: High Per Tag Cost, Shipping Restrictions (due to batteries), Complex Software may be Required, High Interference from Metal and Liquids; Few Global Standards

- Primary Frequency Ranges: 860 - 960 MHz

- Read Range: Near Contact - 25 Meters

- Average Cost Per Tag: $0.09 - $20.00

- Applications: Supply Chain Tracking, Manufacturing, Pharmaceuticals, Electronic Tolling, Inventory Tracking, Race Timing, Asset Tracking

- Pros: Long Read Range, Low Cost Per Tag, Wide Variety of Tag Sizes and Shapes, Global Standards, High Data Transmission Rates

- Cons: High Equipment Costs, Moderate Memory Capacity, High Interference from Metal and Liquids

The relatively wide range of 860 - 960 MHz is recognized as the ‘Global Standard’ for UHF Passive RFID; however, its late adoption led to the range being further divided into two primarily subsets – 865 – 868 MHz and 902 - 928 MHz.

865 - 868 MHz - ETSI - The European Telecommunications Standards Institute (ETSI) is the governing body in Europe that sets and upholds country-wide standards for communicating via multiple channels, including Radio Waves. By ETSI’s regulations, RFID equipment and tags are only allowed to communicate on the smaller frequency range of 865 - 868 MHz because other types of radio communications are allocated to subsets of the larger range of 860 - 960 MHz.

Because ETSI sets the standards for Europe, but when purchasing tags and equipment, the standard can be called either ETSI or EU denoting Europe.

902 - 928 MHz - FCC - The Federal Communications Commission (FCC) is the governing body in the United States that sets and upholds country-wide standards for communicating via multiple channels including Radio Waves. The FCC regulations state that RFID tags and equipment can only operate between 902 - 928 MHz, because, like Europe, other communication types are allocated to the remaining portions of the larger range of 860 - 960 MHz.

RFID Equipment or Tags that are FCC certified or on the North American Frequency Range, or NA, can be used throughout North America.

Other - Because both ETSI and FCC were the first major standards to be approved, many countries either adopted one or the other, or created their own standards* within a subset of either frequency range. For example, Argentina chose to adopt the FCC range of 902 – 928 MHz, while Armenia chose to implement its own, smaller band of 865.6 – 867.6 MHz within the ETSI range.

Although regional regulations like FCC and ETSI are typically discussed using frequency ranges, there are other specifics that each country regulates such as the amount of radiated power (ERP or EIRP). Certain countries are stricter and regulate where RFID can be used, the amount of frequency “hopping” that must be used, or that a license is required to use RFID.

Applications

Applications

Examples of applications that benefit from RFID are endless. Applications extend from broad areas like inventory tracking to supply chain management and can become more specialized depending on the company or industry. Types of RFID applications can span from IT asset tracking to textile tracking and even into specifics like rental item tracking.

What sets a potential RFID application apart from applications that can use other types of systems is the need to uniquely identify individual items quickly and more efficiently where traditional systems fall short. Below are a few applications that are successfully using RFID technology.

| APPLICATION WITHIN INDUSTRY | |||||

| S.No | Industry Applications | S.No | Industry Applications | S.No | Industry Applications |

| 1 | Race Timing | 11 | Vehicle Tracking | 21 | Library Material Tracking |

| 2 | Supply Chain Management | 12 | Toll Booth Management | 22 | Marketing Campaigns |

| 3 | Pharmaceutical Tracking | 13 | Hospital Infant Tracking | 23 | Location Tracking |

| 4 | Inventory Tracking | 14 | Animal Tracking | 24 | Real-time Tracking |

| 5 | IT Asset Tracking | 15 | Tool Tracking | 25 | |

| 6 | Textile Industry | 16 | Jewelry Tracking | 26 | |

| 7 | File Tracking | 17 | Retain Inventory Tracking | 27 | |

| 8 | Returnable Transit Item (RTI) Tracking | 18 | Pipe and Spool Tracking | 28 | |

| 9 | Event / Attendee Tracking | 19 | Logistic Tracking | 29 | |

| 10 | Access Control | 20 | Material Management | 30 | |

Critical Considerations before RFID Implementation

Return on Investment (ROI) - When considering purchasing and deploying any new system, two of the most important questions to answer are if and when the company will see a return on its investment. Fixed costs, recurring costs, as well as the cost of switching in terms of labor costs, all must be evaluated before implementing a new system.

Before implementing an RFID system, both Application Feasibility and Cost Feasibility should be assessed.

Application Feasibility - Application Feasibility refers to the process of determining if the application is suitable for use with RFID. Like all technology, RFID has limitations. Environmental constraints, read range limitations, and asset material composition are just a few of the different aspects that can severely impact how effective an RFID system is for a specific application. The Application Feasibility process should entail scoping of the project and the project’s environment as a starting point, and then determining if RFID (or another technology) is the right fit for the application.

Cost Feasibility - Cost Feasibility refers to assessing if implementing an RFID system is achievable from a monetary perspective. Cost Feasibility includes not just if an ROI is possible, but it also includes working with current numbers and prospective numbers to determine the estimated timeline for a return on investment. RFID systems can be expensive. They require an initial investment for testing and working with different types of equipment and tags (which may be a sunk cost for the company if the technology doesn’t pan out). After the testing phase, deployment costs begin (Read more about Fixed vs. Recurring Costs below). Only after a system has been implemented and is working properly can the timeline begin for seeing a return on the investment.

Fixed vs. Recurring Costs - Grouping costs by fixed (initial) or recurring will help to paint a more accurate picture of expected yearly costs and return on investment of a system.

Fixed Costs - Fixed costs are one-time costs that are associated with getting started. In an RFID deployment, a fixed cost is typically associated with hardware like readers, antennas, and cables needed to setup the system. Fixed costs do not necessarily mean that you will not ever purchase that item again, it just means that the item is not used once and then discarded or consumed during the application. If you plan to set up an initial system and then expand that system later, hardware will still be considered a Fixed Cost. RFID tags are only considered to be a fixed cost when they are continually reused throughout the system – e.g. access control RFID fobs that are assigned and redistributed as needed to employees.

Recurring Costs - Recurring costs are attributed to items that are used once and then discarded or consumed during the application. An RFID inlay or label is a common example of a recurring cost in an RFID system. Because of their low-cost, these tags are frequently applied once and kept on an item for its lifespan (or discarded after use). If an RFID printer is used, then printer ribbon would also be a recurring cost. If a software license renews annually or is purchased as a SaaS (Software as a Service) product, then it too should be factored as a recurring cost.

Environmental Factors - RFID systems can be susceptible to certain materials and environmental factors that can cause diminished read ranges and affect overall system accuracy. Metal and liquids are the two most common sources of interference for RFID applications, but they can be mitigated with the proper RFID tags, equipment, and planning.

As UHF RFID becomes more commonly used with liquid-filled items or metallic items, more and more tags are released with new ways to lessen these problems. In addition, techniques have been developed that can help mitigate the effects of these items, like working with tag placement and spacers.

RFID SYSTEMS - Critical Component

While each system will vary in terms of device types and complexity, every RFID system contains at least the following four components:

- Readers

- Antennas

- Tags

- Cables

The simplest system can be comprised of a mobile handheld RFID reader (with an integrated antenna) and RFID tags, while more complex systems are designed using multi-port readers, GPIO boxes, additional functionality devices (e.g. stack lights), multiple antennas and cables, RFID tags, and a complete software setup.

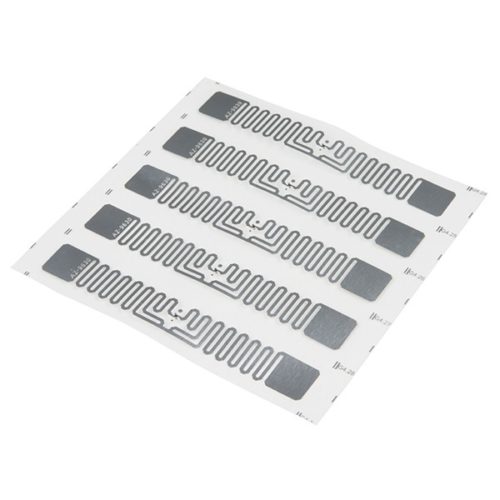

RFID TAGS

An RFID tag in its most simplistic form, is comprised of two parts – an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) which stores the tag’s ID and other information. RFID tags are affixed to items in order to track them using an RFID reader and antenna.

An RFID tag in its most simplistic form, is comprised of two parts – an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) which stores the tag’s ID and other information. RFID tags are affixed to items in order to track them using an RFID reader and antenna.

RFID tags transmit data about an item through radio waves to the antenna/reader combination. RFID tags typically do not have a battery (unless specified as Active or BAP tags); instead, they receive energy from the radio waves generated by the reader. When the tag receives the transmission from the reader/antenna, the energy runs through the internal antenna to the tag’s chip. The energy activates the chip, which modulates the energy with the desired information, and then transmits a signal back toward the antenna/reader.

On each chip, there are four memory banks – EPC, TID, User, and Reserved. Each of these memory banks contains information about the item that is tagged or the tag itself depending on the bank and what has been specified.

Hundreds of different RFID tags are available in many shapes and sizes with features and options specific to certain environments, surface materials, and applications.

Types of RFID TagsBecause there is such wide variety of RFID applications, there are also a wide variety of RFID tags and ways to categorize them. A common way to divide tags into types is inlays vs. hard tags. Inlays are cheaper, typically varying between $0.09 - $1.75 depending on the features on the tags. Hard tags are generally more rugged and weather resistant and vary between $1.00 - $20.00.

- Form Factor – Inlay, Label, Card, Badge, Hard Tag

- Frequency Type– LF, NFC, HF, UHF Passive (902 – 928 MHz, 865 – 868 MHz, or 865 – 960 MHz), BAP, Active

- Environmental Factors– Water resistant, Rugged, Temperature resistant, Chemical resistant

- Customizable– Shape, Size, Text, Encoding

- Specific Features/Applications– Laundry Tags, Sensor Tags, Embeddable Tags, Autoclavable Tags, Vehicle Tags, High Memory Tags

- Specific Surface Materials– Metal mount tags, Glass mount tags, Tags for Liquid-filled items

Tag Pricing

Tag pricing depends on the type of tag and the quantity that are being ordered. As mentioned previously, inlays typically vary between $0.09 - $1.75 and hard tags can vary between $1.00 - $20.00. The higher the level of customization or the more specialized the tag, the more expensive it will be in comparison to typical off-the-shelf tags.

Selecting an RFID Tag- What type of surface will you be tagging? On metal, plastic, wood, etc.?

- What read range do you desire?

- Size limitations (i.e. the tag can be no larger than x by y by z inches)?

- Any excessive environmental conditions to consider? Excessive heat, cold, moisture, impact, etc.?

- Method of attachment? Adhesive, epoxy, rivets/screws, cable ties, etc.?

- The key to choosing a tag is thorough testing of a variety of tags in your environment on the actual items you wish to tag. RFID tag sample packs can be customized for your application so that you can narrow down the tags that are right for your application.

RFID READER

An RFID reader is the brain of the RFID system and is necessary for any system to function. Readers, also called interrogators, are devices that transmit and receive radio waves in order to communicate with RFID tags. RFID readers are typically divided into two distinct types – Fixed RFID Readers and Mobile RFID Readers. Fixed readers stay in one location and are typically mounted on walls, on desks, into portals, or other stationary locations.

An RFID reader is the brain of the RFID system and is necessary for any system to function. Readers, also called interrogators, are devices that transmit and receive radio waves in order to communicate with RFID tags. RFID readers are typically divided into two distinct types – Fixed RFID Readers and Mobile RFID Readers. Fixed readers stay in one location and are typically mounted on walls, on desks, into portals, or other stationary locations.

A common subset of fixed readers is integrated readers. An integrated RFID reader is a reader with a built-in antenna that typically includes one additional antenna port for the connection of an optional external antenna as well. Integrated readers are usually aesthetically pleasing and designed to be used for indoor applications without a high traffic of tagged items.

Mobile readers are handheld devices that allow for flexibility when reading RFID tags while still being able to communicate with a host computer or smart device. There are two primary categories of Mobile RFID readers – readers with an onboard computer, called Mobile Computing Devices, and readers that use a Bluetooth or Auxiliary connection to a smart device or tablet, called Sleds.

Fixed RFID Readers typically have external antenna ports that can connect anywhere from one additional antenna to up to eight different antennas. With the addition of a multiplexer, some readers can connect to up to 32 RFID antennas. The number of antennas connected to one reader depends on the area of coverage required for the RFID application. Some desktop applications, like checking files in and out, only need a small area of coverage, so one antenna works well. Other applications with a larger area of coverage, such as a finish line in a race timing application typically require multiple antennas to create the necessary coverage zone.

Types of RFID ReadersThe most common way to categorize readers is to classify them as either fixed or mobile. Other ways to differentiate between RFID readers include categories like connectivity, available utilities, features, processing capabilities, power options, antenna ports, etc.

- Frequency Range- 902 – 928 MHz US, 865 – 868 MHz EU, Etc.*

- Mobility– Fixed Readers, Integrated Readers; Mobile Readers

- Connectivity Options– Wi-Fi, Bluetooth, LAN, Serial, USB, Auxiliary Port

- Available Utilities– HDMI, GPS, USB, Camera, GPS, GPIO, 1D/2D Barcode, Cellular Capabilities

- Processing Capabilities– OnBoard Processing, No OnBoard Processing

- Power Options– Power Adapter, PoE, Battery, In-Vehicle, USB

- Available Antenna Ports– No External Ports, 1-Port, 2-Port, 4-Port, 8-Port, 16-Port

A reader will usually be the most expensive component in an RFID system. RFID readers can vary from around $400 to up to $3,000 or more depending on the features and capabilities required. One of the less-expensive classes of readers is USB readers, which has an average price point of around $400. USB readers generally have short read ranges and are used for desktop applications. Handheld readers and fixed readers vary greatly in pricing depending on features and functionality offered.

Selecting an RFID Reader- How much read range do you require for your application?

- Any excessive environmental conditions to consider? Excessive heat, cold, moisture, impact, etc.?

- Will you be adding the reader to a network?

- Where will the reader be placed? Fixed location, or on a vehicle?

- Does the reader need to be mobile?

- How many read points/read zones will you need?

- How many tags might need to be read at one time?

- How quickly will the tags be moving through the read zone? For example, is this a slow-moving conveyor belt or fast-moving race?

RFID ANTENNA

RFID Antennas are necessary elements in an RFID system because they convert the RFID reader’s signal into RF waves that can be picked up by RFID tags. Without some type of RFID antenna, whether integrated or standalone, the RFID reader cannot properly send and receive signals to RFID tags.

RFID Antennas are necessary elements in an RFID system because they convert the RFID reader’s signal into RF waves that can be picked up by RFID tags. Without some type of RFID antenna, whether integrated or standalone, the RFID reader cannot properly send and receive signals to RFID tags.

Unlike RFID readers, RFID antennas are dumb devices that receive their power directly from the reader. When the reader’s energy is transmitted to the antenna, the antenna generates an RF field and, subsequently, an RF signal is transmitted to the tags in the vicinity. The antenna’s efficiency in generating waves in a specific direction is known as the antenna’s gain. To put it simply, the higher the gain, the more powerful, and further-reaching RF field an antenna will have.

The RFID antenna gives off RFID waves along a horizontal or vertical plane, which is described as the antenna’s polarity. If the RF field is a horizontal plane, is it described as horizontally linear, and the same principle applies to an RFID antenna that creates a vertical plane.

An antenna’s polarity can have a significant impact upon a system’s read range. The key to maximizing read range is to ensure an antenna’s polarity aligns with the polarity of the RFID tag. If these do not match up, for instance, a vertical linearly-polarized antenna and a tag with a horizontal linearly-polarized antenna, the read range will be severely reduced.

A circularly-polarized antenna transmits waves that continually rotate between horizontal and vertical planes in order to give an application enhanced flexibility by allowing for RFID tags to be read in multiple orientations. However, because the energy is divided between two planes, a circularly-polarized antenna’s read range is shorter versus a similar gain linear antenna.

Types of AntennasRFID Antennas, like most RFID equipment, can be divided into different categories that help to narrow down the best antenna for an application. Even though antennas are grouped by a few different factors, the most common groupings for RFID Antennas are polarity (circular vs linear) and ruggedness (indoor vs. outdoor).

- Frequency Range– 902 – 928 MHz, 865 – 868 MHz, 860 – 960 MHz

- Polarity– Circular, Linear

- Ruggedness– Indoor IP Rated, Outdoor IP Rated

- Read Range– Proximity (Near-Field), Far-Field

- Mounting Type– Shelf Antenna, Ground Antenna, Panel Antenna, Portal Antenna

Most RFID antennas are typically priced between $50 and $300 per antenna, but there are a few that cost more because of key, application-specific factors, such as ground/mat antennas. These antennas are specialized for applications such as race timing and must be rugged enough to survive and perform well while people, bikes, or even go-carts run over them. Specialized antennas can increase a system’s cost significantly but are also an investment that can be the difference between a functioning and non-functioning system.

Selecting an RFID Antenna- How much read range do you need?

- Is it possible to always know or control the orientation of the RFID tag relative to the antenna’s position in your application?

- Any excessive environmental conditions to consider? Excessive heat, cold, moisture, impact, etc.?

- Will the antenna be mounted indoors or outdoors?

- Size limitations (i.e. the antenna can be no larger than x by y by z inches)?

Kits & Additional Items

Development Kits

An RFID Development Kit is a kit put together usually by the reader manufacturer and includes everything needed to get started reading and writing RFID tags. Development Kits are recommended as the best way to start using RFID technology because it allows people to jump right into the technology and start testing their application. Because these kits are typically made by the reader manufacturer, there are many to choose from that combine the manufacturer’s reader with a recommended antenna and some sample RFID tags to test. Development Kits also typically include a sample program for reading and writing RFID tags, as well as access to the manufacturer’s Software Development Kit, or SDK. An SDK contains documentation about the reader, as well as API access and code samples, so that a software developer can begin writing software for the application.

An RFID Development Kit is a kit put together usually by the reader manufacturer and includes everything needed to get started reading and writing RFID tags. Development Kits are recommended as the best way to start using RFID technology because it allows people to jump right into the technology and start testing their application. Because these kits are typically made by the reader manufacturer, there are many to choose from that combine the manufacturer’s reader with a recommended antenna and some sample RFID tags to test. Development Kits also typically include a sample program for reading and writing RFID tags, as well as access to the manufacturer’s Software Development Kit, or SDK. An SDK contains documentation about the reader, as well as API access and code samples, so that a software developer can begin writing software for the application.

RFID Cables

RFID Antenna Cables facilitate communication between the RFID reader and RFID antenna. Without the cable, the reader cannot power and send signals to the tags via the antenna. Choosing an RFID cable may seem like an easier task than choosing other components; however, cables can vary greatly in three specific ways – connector types, length, and thickness/insulation rating – so, it is important to take all three into consideration before purchasing.

RFID Antenna Cables facilitate communication between the RFID reader and RFID antenna. Without the cable, the reader cannot power and send signals to the tags via the antenna. Choosing an RFID cable may seem like an easier task than choosing other components; however, cables can vary greatly in three specific ways – connector types, length, and thickness/insulation rating – so, it is important to take all three into consideration before purchasing.

When determining the right connectors for either end of the cable, first look at the connectors on the RFID reader and the antenna. For example, if an RFID reader has an RP-TNC Female connector, one side of the cable should have an RP-TNC Male connector and vice-versa. For more information on the different types of cable connectors, check out our RFID Cable Guide.

The cable length and thickness (also called insulation rating) will vary depending on your specific solution. The length of the cable is usually determined by how far apart the RFID reader and antenna are, but it’s important to note that, the longer the cable, the more power will be lost in transit.

One way to combat that power loss it to use a higher insulation rating. The longer the length of the cable, the better insulated the cable needs to be in order to maximize efficiency and reduce the amount of power lost along the length of the cable. Of note, as the insulation rating increases, the cable will be thicker and more rigid, which will make it more difficult to bend and work with when turning corners or running through conduit.

Other Equipment & Accessories

A few other system additions and accessories are available either to enhance a system’s functionality or for ease-of-use. For example, RFID printers, RFID portals, GPIO adapters, antenna mounting brackets, and RF power mappers will all supplement or augment your system.

RFID Market and Future Trends and Technology 2020-2025

The global RFID Market is projected to be valued at USD 22 billion in 2020 and is projected to reach USD 33 billion by 2025, growing at a CAGR of 7.36% from 2019 to 2025.

The global RFID Market is projected to be valued at USD 22 billion in 2020 and is projected to reach USD 33 billion by 2025, growing at a CAGR of 7.36% from 2019 to 2025.

- Innovative Manufacturing Will Create Durable and Versatile Tags - Advancements in printed electronics have helped create new classes of extremely thin, flexible RFID tags that can now be combined with printed sensors, printed batteries, thin-film photovoltaic solar cells, and other technologies. With new electronic printing and conductive ink technologies, companies could conceivably print their own chipless RFID tags on site. There are also companies working on 3D printing technology that would enable direct printing of electronics in products as they are rendered. While the printing of RFID tags directly inside products may be several years away, the technology is rapidly evolving to do so.

- New Antenna Designs with Increased Range - The key to good tag performance is the antenna design. It’s the antenna that helps determine where and how a tag can be used, and how well it will perform. Over the next few years, expect to see new antennas and inlays as the competition for RFID antenna design heats up.

- Increased Memory Will Create Smart Tags - Building intelligence into the tag and, by extension, the asset being tagged is another key activity. Expect tags with more memory at a lower cost to enable these “smart asset” applications. High-value assets will be an early application for this technology, as the cost of those assets will make it easier to amortize the increased cost of the more robust tags

- Sensor Integration to Streamline Business - RFID will increasingly be one part of a whole ecosystem of sensors and communication technologies that will help companies better monitor and manage assets and shipments. Passive sensors for temperature, moistures, pressure, vibration and other factors will be combined with RFID to provide even more intelligence form the edge of the enterprise.

- Secure Data With New Cloud-Based Capabilities - RFID can potentially enable a whole host of new applications in the retail, healthcare, manufacturing and other sectors, but one stumbling block has always been management of the data flowing in from thousands of tags. With cloud-based applications and services taking the heavy lifting of IT support away from the point of activity, companies can now deploy centrally managed and centrally available solutions without the traditional support and deployment costs.

- RFID and Blockchain - The combination of RFID and blockchain technologies could do a lot of benefits in supply chain management. Since supply chains often involve many stakeholders, sharing a unique blockchain ensures the collected data are immutable and the exchanged goods are authenticated. As a result, the supply chain is prevented from potential frauds. Without a blockchain, the collected data could be changed by other users. Therefore, there is no completely reliable visibility over the entire supply chain. Once the data is stored in the blockchain, there is no way to change it or delete it. Reliable and verified information is accessible at any time from any of the stakeholders. However, to collect transparently this information, the physical items have to be connected with the digital world. That part can be achieved by using RFID. We can uniquely identify any item by putting an RFID tag on it. Data about the items are then automatically and transparently collected using RFID readers. The collected data, which contains reliable information about the goods used in the supply chain, is then stored in a blockchain. If RFID and blockchain technologies are used in supply chain management, human factor and intentional false information will be eliminated. Different stakeholders will be able to trust that the gathered and stored information is valid. Such a solution automates a significant amount of manual tasks, and thus spares time and money eliminating the lost assets and ensuring that staff focuses on more meaningful assignments. This combination of technologies can be applied in any industry.

General Frequency Range: 30 - 300 kHz

General Frequency Range: 30 - 300 kHz Primary Frequency Range: 13.56 MHz

Primary Frequency Range: 13.56 MHz Applications

Applications

Leave a Reply